55kw 75hp screw air compressor

What matters is not the initial cost, but the life cycle cost !

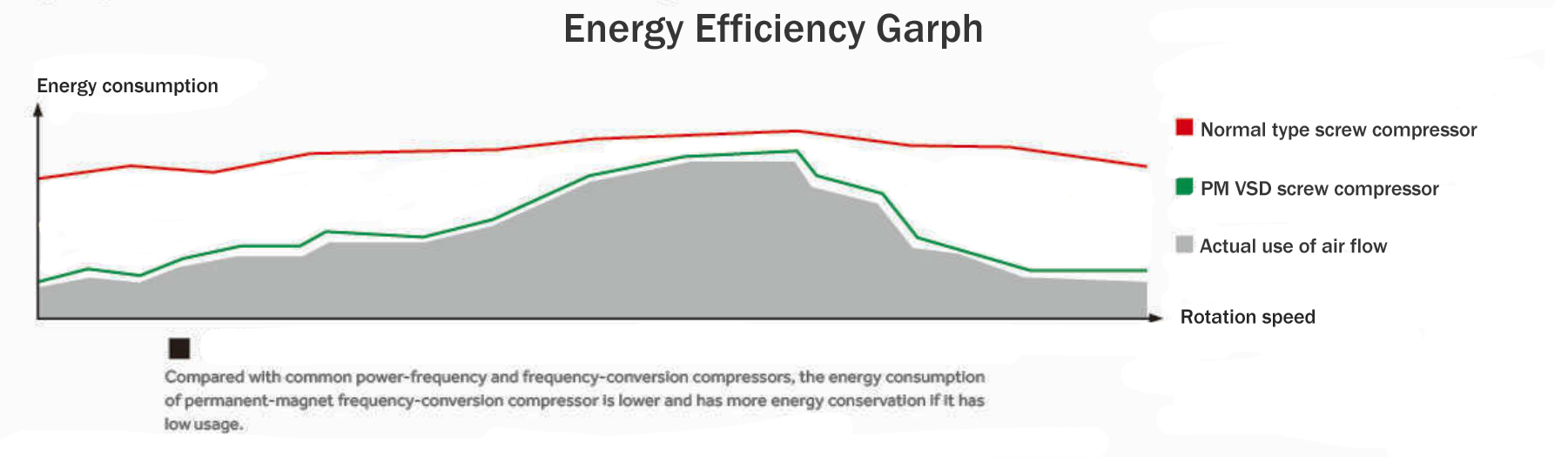

Hengchaowin PM VSD screw type air compressors are more expensive to sell than fixed speed screw air compressor models, but many customers choose them because they know the importance of life cycle cost and return on investment when choosing a compressor.

In a competitive market environment, whether to reduce costs is an important issue for you to consider. With PM frequency conversion technology, you can save energy, thereby greatly reducing electricity bills.

The compressor capacity is automatically adjusted to the precise air demand, and you only need a minimum amount of energy, so saving energy is good for you and good for the environment.

Hengchaowin's self-developed permanent magnet variable frequency screw air compressor is a high-efficiency energy-saving product. It has made a new breakthrough in the performance of the air compressor, and the efficiency of the conventional air compressor is increased by more than 35%.

We are reduce energy costs in the following ways:

1. Eliminate the invalid transition period from full load to no load,

2. Avoid excessive no-load power consumption,

3. Keep the net pressure section,

4. Reduce the overall average operating pressure,

5. If the system pressure is low, the system leakage can also be minimized,

6. The soft-start motor is adopted to accelerate gradually, improve flexibility, and avoid huge impact of power surge.

Products details:

1. permanent magnet motor.

Exceed IE4 standards

IP54 or IP55 protecting grad

Variable speed drive

2. Germany technology air end

R&D in Germany GU or Hanbell brand air end

New improved rotor profile

designed for 10 years +of reliable operation

3.Inlet valve

Optimizes the inlet flow of the air end

No blow-off losses/large suction are

Full aluminum design,maintenance-free

4.oil gas tank & built in separation system.

Oversized air end oil tank improves the cyclone effect maximising the separation process

The high efficiency oil seperator ensures that the oil carry over in less than 3ppm.

System pressure loss,less than 0.02mpa.

5. Polt touch controller

7.0 inch full color touch LCD screen

Operation record/chart display

Weekly timer/service history and planning

Real-time operation/maintenance/alarm information

6.Innovative vectorial inverter

CE,UL,CUL,ROSH certification

Meet EMC c3 and c2 requirements

Independent cooling air duct design

Robust enclosure for trouble-free operation in the harshest conditions.

Technical Parameters:

| Model | Working Pre ure | Air Delivery | Motor Power | Type of Driving | Dimension(mm) | Weight | Output pipe | ||||

| psig | bar | cfm | m3/min | kw/hp | L | W | H | (kg) | Diameter | ||

| HWV-7A | 116 | 8 | 21-42 | 0.6-1.2 | 7.5kw/10hp | Integrated motor | 1000 | 700 | 830 | 200 | 1/2" |

| 145 | 10 | 17-38 | 0.5-1.1 | ||||||||

| HWV-11A | 116 | 8 | 24-63 | 0.7-1.8 | 11kw/15hp | 1050 | 750 | 1000 | 310 | 3/4" | |

| 145 | 10 | 21 -60 | 0.6-1.7 | ||||||||

| HWV-15A | 100 | 7 | 33.9-84.7 | 0.96-2.4 | 15/20 | 1180 | 850 | 1280 | 370 | 1" | |

| 116 | 8 | 31.1-77.6 | 0.88-2.2 | ||||||||

| 145 | 10 | 29.7-74.2 | 0.84-2.1 | ||||||||

| 181 | 12.5 | 25.4-63.6 | 0.72-1.8 | ||||||||

| HWV-22 A | 100 | 7 | 53.7-134.2 | 1.5-3.8 | 22/30 | 1200 | 850 | 1280 | 520 | 1" | |

| 116 | 8 | 50.8-127.1 | 1.4-3.6 | ||||||||

| 145 | 10 | 45.2-113.0 | 1.3-3.2 | ||||||||

| 181 | 12.5 | 39.5-88.3 | 1.1-2.8 | ||||||||

| HWV-30 A | 100 | 7 | 74.9-187.1 | 2.1-5.3 | 30/40 | Split motor | 1450 | 1000 | 1465 | 520 | 11/4" |

| 116 | 8 | 70.6-176.6 | 2.0-5.0 | ||||||||

| 145 | 10 | 60.7-151.8 | 1.7-4.3 | ||||||||

| 181 | 12.5 | 50.8-127.1 | 1.4-3.6 | ||||||||

| HWV-37 A | 100 | 7 | 93.2-233.0 | 2.6-6.6 | 37/50 | 1450 | 1000 | 1465 | 720 | 11/4" | |

| 116 | 8 | 87.6-218.9 | 2.5-6.3 | ||||||||

| 145 | 10 | 80.5-201.3 | 2.3-5.7 | ||||||||

| 181 | 12.5 | 65.0-162.4 | 1.8-4.6 | ||||||||

| HWV-45 A | 100 | 7 | 113.0-282.5 | 3.2-8.0 | 45/60 | 1450 | 1000 | 1465 | 720 | 2" | |

| 116 | 8 | 108.8-271.9 | 3.1-7.7 | ||||||||

| 145 | 10 | 94.6-243.6 | 2.7-6.7 | ||||||||

| 181 | 12.5 | 84.7-211.9 | 2.4-6.0 | ||||||||

| HWV-55 A | 100 | 7 | 148.3-370.8 | 4.2-10.5 | 55/75 | 2100 | 1700 | 1480 | 2" | ||

| 116 | 8 | 138.4-346.0 | 3.9-9.8 | ||||||||

| 145 | 10 | 122.9-307.2 | 3.5-8.7 | ||||||||

| 181 | 12.5 | 103.1-257.8 | 2.92-7.3 | ||||||||

| HWV-75A | 100 | 7 | 192.1-480.2 | 5.4-13.6 | 75/100 | 2100 | 1250 | 1700 | 1640 | 2" | |

| 116 | 8 | 183.6-459.0 | 5.2-13.0 | ||||||||

| 145 | 10 | 159.6-399.0 | 4.5-11.3 | ||||||||

| 181 | 12.5 | 142.7-356.6 | 4.0-10.1 | ||||||||

| HWV-90 A | 100 | 7 | 228.8-572.0 | 6.5-16.2 | 90/120 | 2170 | 1320 | 1750 | 1860 | 2" | |

| 116 | 8 | 217.5-543.8 | 6.2-15.4 | ||||||||

| 145 | 10 | 186.4-466.1 | 5.3-13.2 | ||||||||

| 181 | 12.5 | 158.2-395.5 | 4.5-11.2 | ||||||||

| HWV-110 A | 100 | 7 | 293.8-734.45 | 8.3-20.8 | 110/150 | 2545 | 1500 | 1900 | 2600 | DN65 | |

| 116 | 8 | 275.4-688.5 | 7.8-19.5 | ||||||||

| 145 | 10 | 233.0-582.6 | 6.6-16.5 | ||||||||

| 181 | 12.5 | 193.5-483.7 | 5.5-13.7 | ||||||||

| HWV-132A | 100 | 7 | 339.0-847.4 | 9.6-24 | 132/175 | 2545 | 1500 | 1900 | 2900 | DN65 | |

| 116 | 8 | 324.9-812.1 | 9.2-23 | ||||||||

| 148 | 10 | 282.5-706.2 | 8.0-20.6 | ||||||||

| 181 | 12.5 | 218.9-547.3 | 6.2-15.5 | ||||||||

| HWV-160 A | 100 | 7 | 392.6-981.6 | 11.1-27.8 | 160/200 | 2545 | 1500 | 1900 | 3200 | DN65 | |

| 116 | 8 | 367.2-918.1 | 10.4-26 | ||||||||

| 145 | 10 | 331.9-829.8 | 9.4-23.5 | ||||||||

| 181 | 12.5 | 275.4-688.5 | 7.8-19.5 | ||||||||

FAQ:

Q1: How long could your air compressor be used?

O: Generally, more than 10 years

Q2: What's payment term?

O: T/T, L/C, Paypal and etc. Also we could accept USD, RMB, Euro and other currency (Pls contact our sales for more information

Q3: How about your customer service?

O: 24 hours on-line service available

Q4: How about your after-sales service?